HOME > Company News > Wofu Permanent Magnet has won the bid for the industry benchmark - Conch Cement - for three consecutive years, working together to promote the development of the industry

Recently, Anhui Wofu Permanent Magnet Technology Co., Ltd. successfully won the bid again in the annual spare parts bidding project of Conch Cement with its outstanding technical strength and excellent product quality, and has been the only supplier of annual disc permanent magnet coupling spare parts for three times.

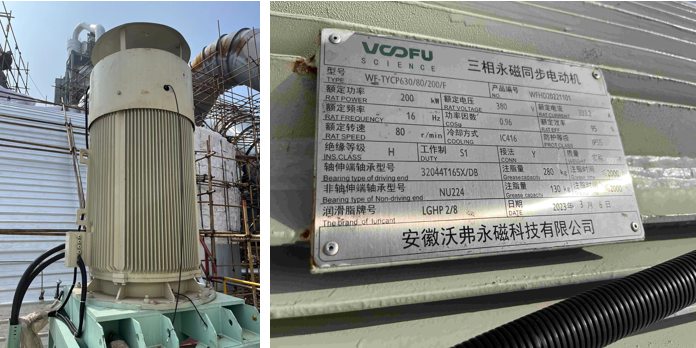

Looking back at the cooperation process, 2022 is an important starting point for both parties' cooperation. In the bidding for the disc type permanent magnet coupling of Hailuo Cement, Wofu Permanent Magnet successfully won the bid and laid a solid foundation for further cooperation between the two parties. In December of the same year, the 200kW/80rpm direct drive permanent magnet motor for the powder selection machine independently developed by Wofu Permanent Magnet won the bid again and was successfully delivered to a factory in Hailuo in March 2023. It will be used as a supporting project for the construction of a 4000 ton new dry process cement clinker production line and a 4 million ton cement grinding system. The direct drive permanent magnet motor of the powder selection machine has significant advantages such as simplifying the transmission chain, improving reliability, and reducing costs, and has won high praise from Conch Cement, further consolidating its foundation as a supplier.

Since then, as an important supplier of Conch Cement Group, Wofu Permanent Magnet has continued to make efforts in cooperation with Conch Cement, deepening its product application fields. With advanced technology, stable product performance, and high-quality services, it has stood out in fierce market competition in multiple projects. By July 2025, it has won bids again in more than 20 bidding projects. Provided disc type permanent magnet couplings for first and second line inclined zipper machines, first line inbound bucket lifts, outbound grinding bucket lifts, belt conveyors, and elevators to various branches of Hailuo Cement Group; Powder selection machine direct drive permanent magnet motor; Cooling tower direct drive permanent magnet motor; More than 20 permanent magnet drives, including direct drive permanent magnet motors for cement grinding and powder selection machines, and permanent magnet drive products with significant advantages such as simplified transmission chains, improved reliability, and reduced costs, have won high praise from Conch Cement and further solidified its foundation as a supplier.

A certain conch waste heat power generation cooling tower is equipped with two 132KW cooling fans. Due to long-term operation, the sealing components of the fan reducer have aged to varying degrees, making it difficult to thoroughly control leakage. Oil leakage can cause pollution to the quality of the system's cooling circulating water and increase the risk of scaling in the heat exchange tubes. Due to the long transmission chain system of the fan, it is difficult to find the correct one, and the carbon fiber connecting rod is prone to damage.

Before renovation: Remove asynchronous motor, reducer, carbon fiber connecting rod, and diaphragm coupling

After renovation: Install permanent magnet direct drive motor and variable frequency control system

After using one 132 kW permanent magnet direct drive motor for the cooling tower fan motor, under the same operating conditions, the average hourly current of a single permanent magnet motor decreases by about 32A under full load in summer. The measured voltage during operation is about 380V. Taking U=380V, cos φ=0.96, and η=0.95, the power is P=1.732UIcos φ η=1.732 × 0.38 × 32 × 0.96 × 0.95=19.2 (kW), and it is expected to save 19.2kWh of electricity per hour under full load in summer; The current drops by about 16%.

At present, the # 2 cooling tower fan is operating at full power frequency, with a current of about 195A and an estimated hourly power consumption of 109kW (as shown in Figure 1). The fan of cooling tower 1 is driven directly by a permanent magnet motor, with a dedicated frequency converter operating at 13.3Hz and a current of 43.5A. The hourly power consumption is estimated to be 15kW by hanging a meter (measured on site for 12 minutes, with meter data shown in Figure 2). The temperature of the motor coil is about 53 ℃, the temperature of the bearings is about 46 to 48 ℃, and the motor vibration is 0.1mm/s. All operating data meet the technical requirements and fully meet the actual production needs (see Figure 3).

Based on the current stable operating conditions, if two cooling tower fans operate simultaneously in summer, the total power consumption can be reduced by 94 kWh compared to operating under the same conditions before the renovation, with a power saving rate of about 45%. Calculated based on a summer operating condition of 2200 hours and an electricity price of 0.4 yuan/kWh, the electricity cost savings in the third quarter are: 94 kWh x 2200 hours x 0.4 yuan/kWh=82720 yuan;

In the first quarter, the outdoor temperature was low. Based on past production experience, only one cooling tower fan needs to be turned on to meet production needs.

In the second and fourth quarters, based on past production experience, the fan of cooling tower 2 will be fully turned on, and the speed of cooling tower fan 1 will be adjusted according to the demand for preheating and power generation circulating water. The energy-saving rate is conservatively estimated to be 50%, and the total power consumption can be reduced by 100kWh. Electricity cost savings in the second and fourth quarters: 100kWh x 4400h x 0.4 yuan/kWh=176000 yuan;

The total electricity consumption saved for the whole year is 646800 kWh, and the total electricity cost saved for the whole year is about 258720 yuan. At the same time, it can reduce 644859kg of carbon dioxide emissions. The energy-saving effect is significant and has been highly recognized by Conch Cement.

As a leading enterprise in the cement industry, Conch Cement has a wide range of influence within the industry. Its selection of suppliers is extremely strict, and Wofu Permanent Magnet has won multiple bids for three consecutive years, fully proving that its products and services fully meet the requirements of Conch Cement for high quality, high performance, and high stability.

The continuous cooperation between both parties has not only brought stable business growth to Wofu Permanent Magnet, but also provided strong support for Hailuo Cement in energy conservation, consumption reduction, and improving equipment operation efficiency. In the future, Wofu Permanent Magnet Technology Co., Ltd. and Conch Cement are expected to deepen cooperation in more fields, work together and contribute more to promoting technological progress and sustainable development in the cement industry and related fields.