HOME > Company News > How does the power plant achieve an energy-saving rate of 76.9% for the permanent magnet motor of the air-cooled island fan

Air cooling island is the core equipment in thermal power plants that uses air as a cooling medium to cool high-temperature steam. In areas with scarce water resources, the air cooling island system of the power plant undertakes the key task of condensing the unit's exhaust steam, and its fan energy consumption has always been an important component of the power plant's operating costs. Traditional air-cooled island fans often adopt the drive mode of asynchronous motors combined with reducers. The maintenance cost of air-cooled island reducers gradually increases with the increase of operating time, and the transmission efficiency is low, resulting in serious energy waste.

Taking a power plant in Shanxi Province as an example, during summer, the motor runs at high speed for a long time, the gearbox failure rate is high, and the equipment operating temperature is high; The material and labor costs for daily maintenance are high. To solve this problem, it has been decided to carry out permanent magnet direct drive transformation on the No. 3 air-cooled fan in the first row of Unit # 1, reducing intermediate mechanical connection links, simplifying transmission methods, reducing system failure points, and achieving maintenance free, energy-saving and other effects.

To solve this problem, the technical team of a power plant in Shanxi has decided to introduce the Wofu air-cooled island permanent magnet direct drive motor technology independently developed by Anhui Wofu Permanent Magnet Technology Co., Ltd. after in-depth research and technical demonstration. The Wofu air-cooled island permanent magnet direct drive motor eliminates the motor end coupling and reducer, and is directly connected to the fan blade hub, fundamentally solving a series of problems caused by gear transmission. Due to the reduction of intermediate transmission links, the application of this technology greatly improves the reliability of motors and loads, reduces equipment maintenance workload, and reduces system vibration without the need for gear lubrication, further reducing maintenance costs and effectively ensuring stable production of power plants. At the same time, the reduction of system vibration also reduces the impact on surrounding equipment and extends the service life of other devices.

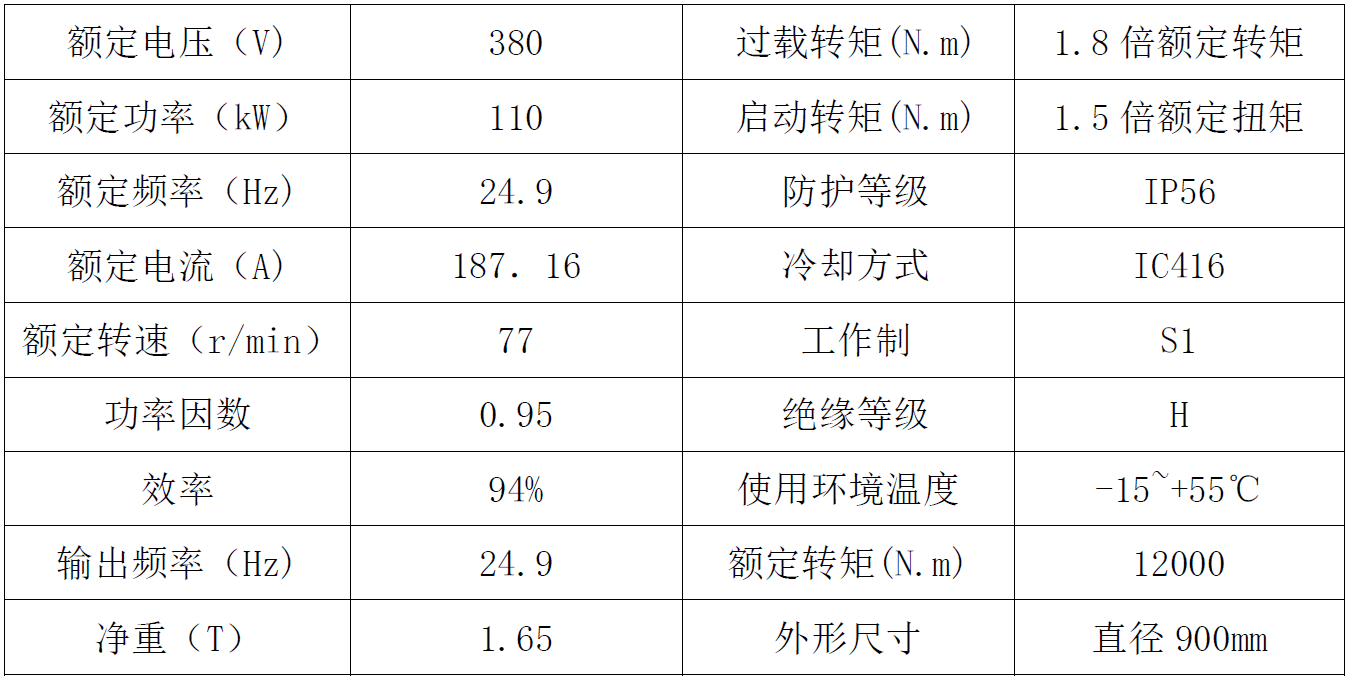

Equipment parameters

Operation analysis

Since the permanent magnet motor was put into operation, the energy-saving effect has been immediate. Through actual monitoring and comparative analysis of collected data, it was found that during high load (69-77rpm) operation, an average energy saving of 5.8% was achieved; When operating at medium load (35-60rpm), the average energy saving is 31%; During low load operation (15-30rpm), the average energy savings are 76.9%. The energy-saving effect is significant.

The successful implementation of the energy-saving renovation project for the permanent magnet motor of the air-cooled island fan in the power plant has not only brought significant economic and environmental benefits to itself, but also provided valuable experience for the energy-saving technology renovation of the power industry. With the deepening of the "dual carbon" goal, more and more power plants are turning their attention to efficient and energy-saving technologies. The permanent magnet motor technology for air-cooled island fans is expected to be widely applied and promoted in the industry, helping the power industry achieve green and low-carbon transformation.