HOME > Company News > Significant achievements have been made in the renovation of permanent magnet motors on the air-cooled island of a power plant in Inner Mongolia

Recently, a power plant in Inner Mongolia has made significant breakthroughs in the field of energy-saving renovation. By implementing the permanent magnet motor renovation project on the air cooling island system, the plant successfully achieved an average energy saving of 43.76%, setting a new benchmark for energy conservation and carbon reduction in the thermal power industry.

As a key component of the power plant cooling system, the operational efficiency of the air cooling island directly affects the energy consumption level of the entire unit. The traditional asynchronous motor drive system is limited in its energy-saving potential due to the complexity of the transmission chain and high energy consumption. A power plant in Inner Mongolia is constructing 2 × 300MW and 2 × 350MW supercritical extraction steam heating units. The cooling method of the unit adopts the air cooling island mode. Currently, there are several problems with the air cooling island fans: 1. After the reducer of the air cooling island fan leaks oil, the oil stains are easily adhered to the electrical equipment below the air cooling island, which can cause pollution flashover accidents of the electrical equipment. 2. The maintenance workload and cost of the air cooling island fan motor and reducer are high. 3. The use of variable frequency control for asynchronous motor speed regulation has resulted in unsatisfactory work efficiency, which poses a challenge to the company's energy conservation and consumption reduction efforts. A power plant in Inner Mongolia actively responded to the national "Action Plan for Industrial Energy Efficiency Improvement", and after multiple inspections and comparisons, introduced the permanent magnet synchronous motor technology of Anhui Wofu Permanent Magnet Technology Co., Ltd. to comprehensively upgrade and transform the air cooling island system.

The main advantages of using the Wofu permanent magnet cooling tower direct drive permanent magnet motor are as follows: 1. It can simplify the power transmission mode and achieve electrical direct drive without gears or lubricating oil, making the system more reliable; 2. Improved the continuous and stable operation time of the equipment, and its torque is transmitted coaxially through the motor air gap, eliminating the faults and problems caused by the contact transmission of gearbox teeth; 3. The gearbox has been cancelled, greatly reducing the workload of maintenance, resulting in a smaller product size and smaller footprint; 4. During the flushing of the air cooling island, the absence of a reducer can prevent the occurrence of electrical equipment pollution flashover accidents caused by oil contamination in the flushing water. Due to its scientific low-speed design, the service life of the equipment has been extended. 6. The energy-saving effect is significant. The operating current range of air-cooled motors is now between 140A-170A. After the transformation of air-cooled permanent magnet motors, not only have certain economic benefits been achieved, but also the safety performance of the unit has been improved.

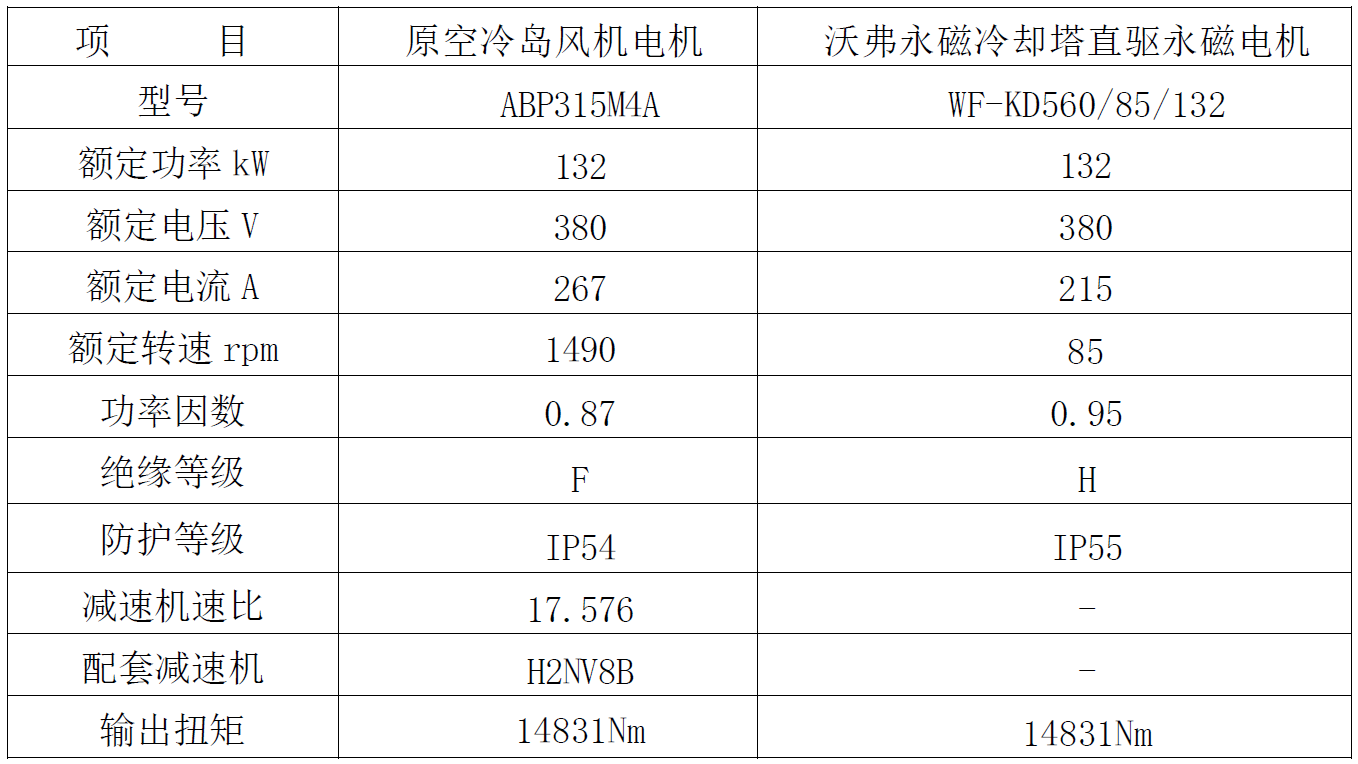

Parameters of the electric motor for the air-cooled island fan in a power plant in Inner Mongolia

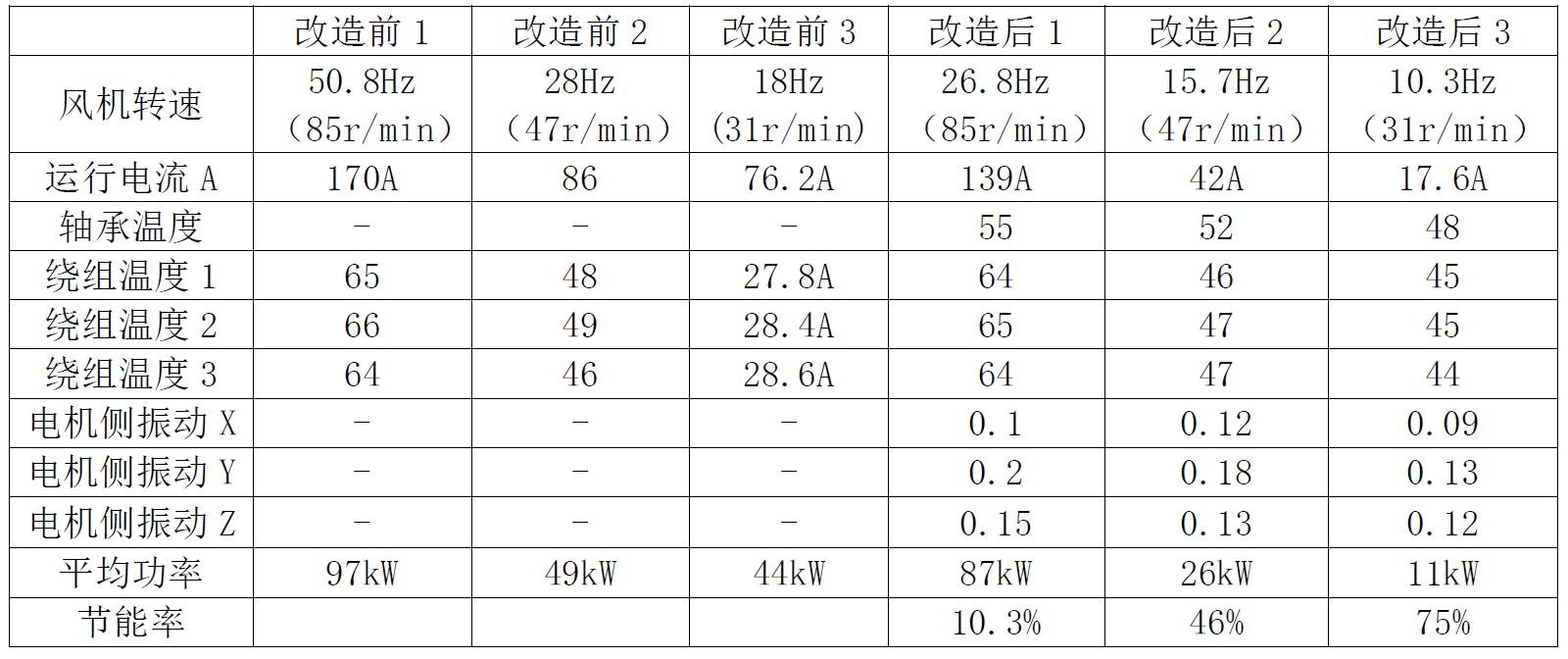

After selecting WF-KD560/85/132 permanent magnet direct drive motor. The running effect is as follows:

On site use is as follows:

The Wofu permanent magnet cooling tower direct drive permanent magnet motor is produced to meet the speed and torque required for heavy-duty equipment operation, achieving direct connection between the permanent magnet direct drive motor and the load equipment. Compared with traditional asynchronous motors, permanent magnet motors no longer reduce speed through reducers and do not require auxiliary transmission equipment. They directly drive loads, simplify the transmission chain, and further reduce system energy consumption. This renovation not only improved the performance of the motor, but also reduced equipment maintenance costs, improved the stability and reliability of system operation, and achieved energy savings of up to 20-50% through national first level energy efficiency certification.

According to actual operational data monitoring, the renovated air cooling island system has achieved significant energy savings under various operating conditions. The average energy-saving rate reached 43.76%, far exceeding industry expectations. This achievement not only brings considerable economic benefits to a power plant in Inner Mongolia, saving a large amount of electricity expenses every year, but also significantly reduces carbon emissions for the enterprise, helping to achieve the "dual carbon" goal.