HOME > Company News > Decoding the Implementation Path of 40% Energy Saving for Condensed Water Pumps in Power Plants

On June 4, 2025, the Ministry of Ecology and Environment of the National Development and Reform Commission announced the launch of the 2025 National Energy Conservation Promotion Week and National Low Carbon Day activities. This is the 35th Energy Conservation Promotion Week in China, and the theme for this year is "Energy Conservation and Efficiency Enhancement, Revitalizing the 'New' Leadership". Energy conservation is a strategic measure to maintain national energy security and a powerful lever to accelerate the transformation and upgrading of industrial structure. From policy guidance to energy conservation and carbon reduction actions in the industrial sector, from upgrading the energy efficiency of household appliances to green choices for people's daily lives, energy conservation and carbon reduction are changing the sustainable development path of China's economy and society in a multidimensional manner.

At present, energy consumption in China's industrial sector accounts for about 2/3 of the total, and carbon emissions account for about 70%, making it an important area for energy conservation and carbon reduction. In the vast system of energy supply, the efficient and stable operation of power enterprises, as a key link, is crucial for economic and social development.

For centrifugal pump equipment, due to safety considerations in design, the actual operating flow rate of the pump is much lower than the rated flow rate. Usually, the output flow is controlled by starting the number of pumps or by using a frequency converter for frequency regulation control. To actively respond to the national "dual carbon" target and break through traditional bottlenecks, Unit 6 of Huaneng Luohuang Power Plant is a 600MW unit equipped with 2 condensate pumps. Previously, ABB variable frequency regulation was used. Due to the approaching expiration of the frequency converter's lifespan, frequent failures, high maintenance costs, and the presence of low-frequency resonance issues, this time a low failure rate, small footprint, and simple operation permanent magnet speed controller was adopted.

#6 sets of condensate pumps, one in use and one as backup, with motor parameters of 2240KW/1489rpm/6KV/246.3A, using Anhui Wofu Permanent Magnet Technology Co., Ltd. oil cooled permanent magnet governor WF-TY875. After renovation, it has been running very stably ever since.

On site installation comparison

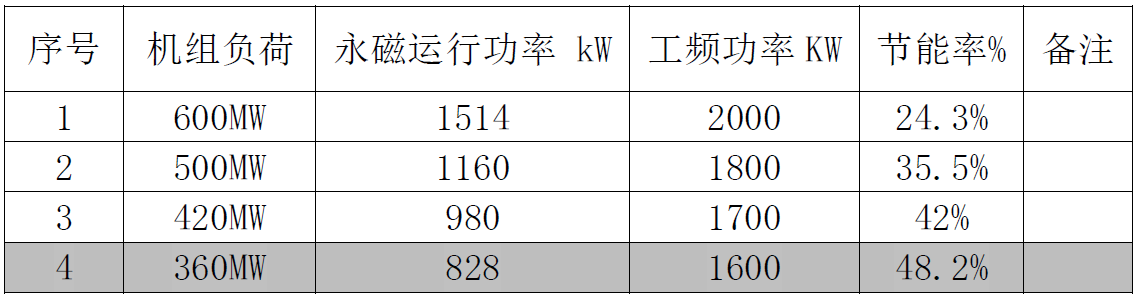

Operating data

Nvestment efficiency

At present, the condensate pump operates at 60% load for a long time, with a power consumption of 828KW. It runs for 8000 hours annually at a cost of 0.5 yuan/kWh. Compared with the same power frequency, it saves 3.088 million yuan annually, with a comprehensive energy saving of over 40%. The energy-saving effect of the condensate pump in Huaneng Luohuang Power Plant is significant, with a return on investment period of less than one year. Low failure rate, minimal vibration, no maintenance since operation, stable and reliable.

In addition, the annual average power generation load of Huaneng Luohuang Power Plant units is around 70%, but the desulfurization system is designed for 100% power generation load without any adjustment means, resulting in serious waste. Therefore, a permanent magnet speed controller has been added to the # 6B slurry circulation pump slurry circulation pump to achieve the goal of speed regulation and energy saving. The slurry circulation pump adopts the permanent magnet speed regulation energy-saving technology of Anhui Wofu Permanent Magnet Technology Co., Ltd. to carry out speed regulation and energy-saving transformation of the circulation pump system. After installation and operation, the equipment is stable, reliable, and has considerable energy-saving effects.

On site installation comparison

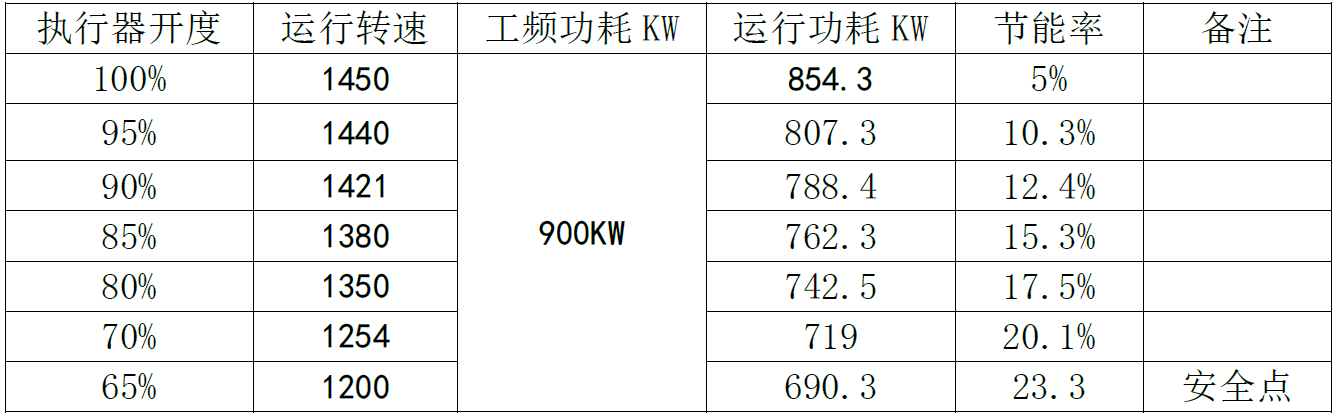

Operating data

The data in the table shows that at a 65% opening, there is an energy saving of 23.3%. The long-term operation of the site at an opening of 70% -80% results in a comprehensive energy saving of about 20%. The energy-saving effect is significant.

Permanent magnet drive technology is a groundbreaking new technology developed internationally in recent years, specifically designed for energy-saving speed regulation of centrifugal loads such as fans and pumps. It has the characteristics of high efficiency, energy saving, high reliability, no rigid connection to transmit torque, can be applied in harsh environments, greatly reduces overall system vibration, reduces system maintenance, and extends system service life. Especially its excellent speed regulation characteristics of not generating high-order harmonics and not causing motor heating at low speeds make it the preferred choice for energy-saving technology transformation of fans and pumps. It has the advantages of wide adjustment range, fast response speed, simple equipment structure, low failure rate, low maintenance cost in the later stage, high reliability, long service life, and can be used for a long time under environmental temperature conditions of -10 ℃ to+50 ℃.

The innovation and breakthrough of permanent magnet drive technology is a crucial step towards its efficient, green, and intelligent development. Not only does it enhance the competitiveness of power plants, but it also provides valuable experience for the sustainable development of the power industry. While ensuring stable energy supply, it safeguards our blue sky and green mountains, contributing to the formation of green and low-carbon production and lifestyle, promoting the comprehensive green transformation of economic and social development, and building a clean and beautiful energy future.