HOME > Company News >

Recently, the energy-saving renovation project of the air cooling island permanent magnet motor in a thermal power plant in Inner Mongolia has been successfully completed and put into operation. After continuous monitoring and verification, the comprehensive energy-saving effect of the air cooling system has been significantly improved, and the stability of equipment operation has been significantly improved. This marks a key step for the power plant in implementing the "dual carbon" goal and promoting the upgrading and transformation of traditional energy, providing a replicable practical model for energy conservation and consumption reduction in the thermal power industry in Inner Mongolia.

As an important component of the northern energy base, this thermal power plant bears the dual responsibility of providing power for industrial production and heating for residents in the region during winter. The air-cooled island system, as the core equipment for condensing exhaust steam of the unit, is a key configuration for power plants in water scarce areas. But the air cooling fan in the first workshop of the power plant now adopts an asynchronous motor and gearbox scheme, which is controlled by a frequency converter for stepless speed regulation. The maintenance cost of the air-cooled island reducer gradually increases with the increase of operating time; In summer, the high-speed operation time of motors is long, and the failure rate of asynchronous motors, speed regulating frequency converters, and reducers is high. The operating temperature of equipment is high, and the material and labor costs of daily maintenance are high. This not only increases the operational burden of enterprises, but also lags behind the development requirements of the national coal-fired power unit "three transformations linkage" (flexibility, energy conservation, and heating transformation).

To solve this problem, after multiple investigations and comparisons, it has been decided to carry out energy-saving transformation of the overall transmission mode of the air-cooled island permanent magnet direct drive motor independently developed by Wofu Permanent Magnet, reducing intermediate mechanical connection links, simplifying the transmission mode, reducing system failure points, improving transmission efficiency, reducing maintenance workload, and achieving energy-saving effects.

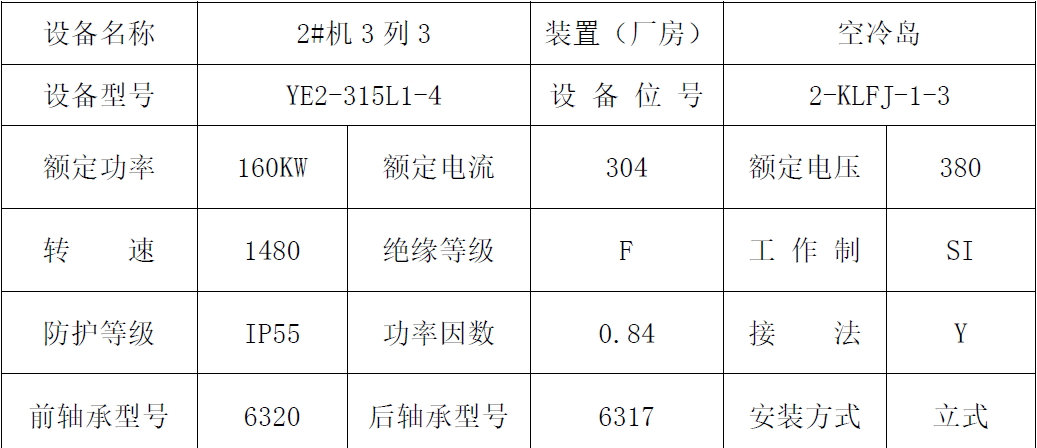

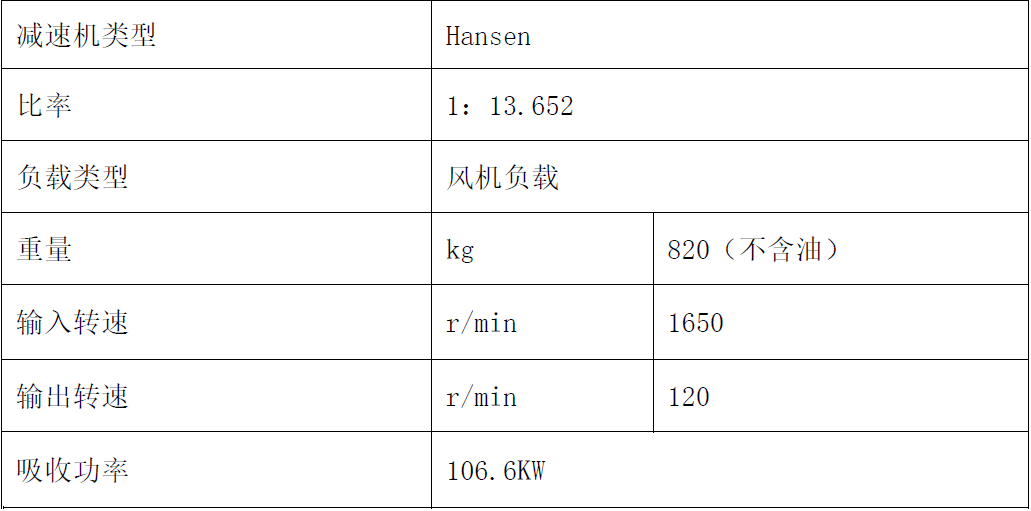

The usage conditions before on-site renovation are as follows:

The equipment parameters are as follows:

When it is necessary to replace asynchronous motors and gearboxes to achieve low-speed high torque operation. We need a low-speed high torque drive motor. Asynchronous induction motors are limited by their own characteristics and cannot achieve low-speed high torque. Permanent magnet motors use rare earth permanent magnet materials to provide the excitation magnetic field for the motor. The stator winding can adopt special winding technology to solve the problems that asynchronous motors cannot solve, and can directly meet the speed and torque requirements of the load.

The characteristics of Wofu permanent magnet air-cooled island direct drive motor technology:

1. High overall system efficiency, by reducing transmission links, improving efficiency, reducing motor load, and achieving significant energy-saving effects;

2. It can achieve excellent control and regulation characteristics, and through variable frequency drive, the speed can be infinitely adjusted to the load within the range of 0-110%;

3. Fewer components mean less maintenance and downtime, as well as space savings;

4. High reliability, minimal maintenance: The equipment has a simple structure, low failure rate, and low maintenance costs.

5. Designing motor technical parameters (such as speed, torque, etc.) separately based on on-site requirements makes it easier and faster to install;

6. Long service life: up to 30 years or more.

On site installation comparison

On the basis of the original equipment, the reducer and auxiliary system were removed, and the fan selection was directly driven by the motor. The original structure and fan system remained unchanged, and the effect of low speed and high torque was directly achieved by the motor. Through experiments and on-site calculations, the maximum torque reached 14020Nm or more.

During the renovation process, the original gearbox control cable and backup channel were used to connect the motor winding temperature and bearing temperature to the DCS system, set alarm values, and implement comprehensive detection and automation control of the motor.

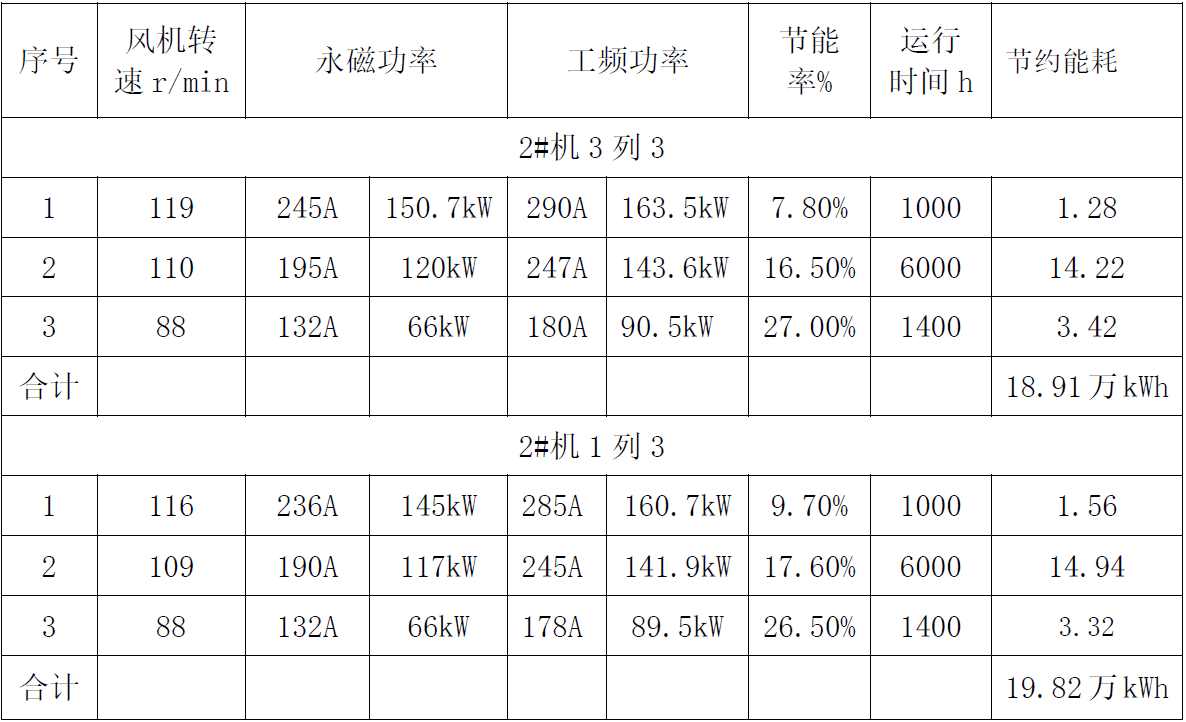

Operation comparison

After the transformation, at the highest speed, the winding temperature does not exceed 82 ℃, the bearing temperature does not exceed 47 ℃, the vibration is normal, and the operation is stable.

investment efficiency

The air-cooled island fan operates year-round, with an average electricity cost of 0.55 yuan/kWh, saving an annual electricity cost of 107000 yuan. At the same time, relying on the high reliability and maintenance free characteristics of permanent magnet motors, it can also reduce the consumption of reducer oil, equipment maintenance, and labor costs by 26000 yuan per year, with an average annual cost savings of 133000 yuan per unit.

Each unit in the air cooling island of the thermal power plant is equipped with 12 air cooling fans, which consume 7% of the plant's electricity. Based on this benefit calculation, the current renovation of two pilot units can create a direct economic benefit of about 266000 yuan per year, while significantly reducing the frequency and intensity of equipment maintenance, significantly improving the stability and safety of unit operation, and achieving significant breakthroughs in energy conservation, cost reduction, and efficiency improvement.

Technological transformation is a key means to promote transformation and upgrading, and an important way to build a sustainable competitive industrial cluster. The technological transformation of the thermal power plant not only brings immediate energy-saving benefits, but also actively responds to the national "dual carbon" strategy and local energy policies, strictly implements the "14th Five Year Plan" energy consumption dual control target, and plays a positive demonstration role in energy-saving transformation of similar units. It promotes the transformation of the coal-fired power industry towards clean, efficient, and flexible regulation, effectively improves the ecological and environmental protection level and economic benefits, and paves the way for high-quality development of green transformation and upgrading, efficient resource utilization, and strengthened innovation and research and development.