HOME > Company News > Energy saving 48.2%! Wofu permanent magnet empowers a power plant in Chongqing to launch a new paradigm of green power generation

Recently, the permanent magnet speed regulation energy-saving renovation project of Unit A condensate pump in a power plant in Chongqing has achieved a leapfrog improvement in equipment operating energy efficiency after energy-saving renovation. The energy-saving rate has been tested to be as high as 48.2%, which can reduce the consumption of standard coal by more than 1000 tons per year, setting an example in the field of high-efficiency energy-saving renovation in the thermal power industry.

For centrifugal pump equipment, due to safety considerations in design, the actual operating flow rate of the pump is much lower than the rated flow rate. Usually, the output flow is controlled by starting the number of pumps or by using a frequency converter for frequency regulation control.

The # 6 unit of a power plant in Chongqing is a 600MW unit equipped with 2 condensate pumps. Previously, ABB variable frequency regulation was used. Due to the approaching expiration of the lifespan of the frequency converter, frequent malfunctions, aging electronic components, high energy consumption, high maintenance frequency, high maintenance costs, and the existence of low-frequency resonance problems, the voltage of the motor rotor shaft increases, which can easily cause bearing oil film rupture and breakdown. There is a gap between the national "dual carbon" target and the requirements of the green development strategy for power plants.

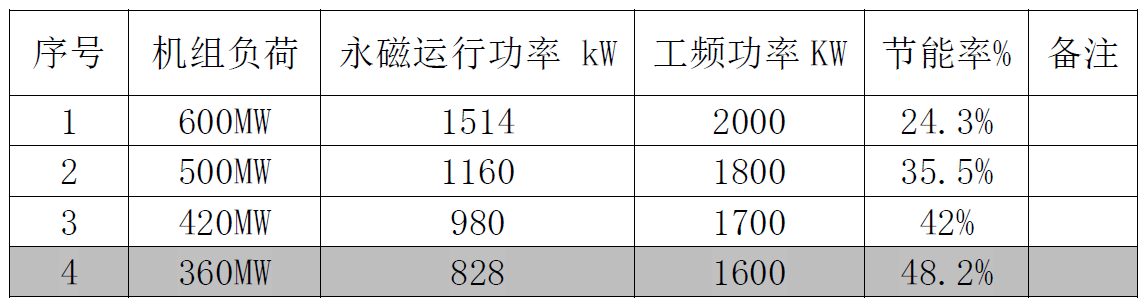

To solve this dilemma, the power plant has launched a special renovation plan, selecting a mechanical adjustment product permanent magnet governor with low failure rate, small footprint, and simple operation through open bidding. The focus is on upgrading the technology of Unit 6's A condensate pump. #6 sets of condensate pumps, one in use and one as backup, with motor parameters of 2240KW/1489rpm/6KV/246.3A, using Anhui Wofu Permanent Magnet Technology Co., Ltd. oil cooled permanent magnet governor WF-TY875. After renovation, it has been running very stably ever since.

A permanent magnet speed controller is a revolutionary transmission device that transmits torque through an air gap. There is no need for mechanical connection between the motor and the load device shaft. When the motor rotates, it drives the magnetic disk to cut magnetic lines in the strong magnetic field generated by the disk containing a strong rare earth magnet, thus generating eddy currents in the magnetic disk. This eddy current generates a repulsive magnetic field on the magnetic disk, pulling the relative motion between the magnetic disk and the motor, thus achieving torque transmission between the motor and the load.

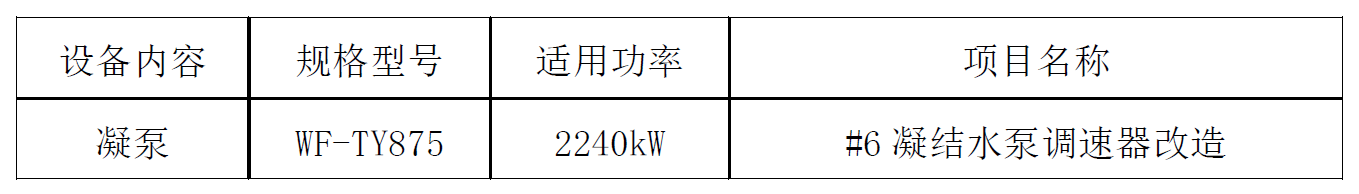

operating data

At present, the condensate pump operates at 60% load for a long time, with a power consumption of 828KW. It runs for 8000 hours annually at a cost of 0.5 yuan/kWh. Compared with the same power frequency, it saves 3.088 million yuan annually, with a comprehensive energy saving of over 40%. The energy-saving effect of condensate water pump is obvious, and the investment return period is less than one year. After installation, the failure rate is reduced, the system runs stably, and the overall operating temperature of the permanent magnet governor is relatively low. The vibration of the equipment has decreased, and low-speed resonance no longer occurs. The vibration values are all below 2.8mm/s. It has been running steadily and reliably so far, and is very worthy of promotion.

It is reported that Wofu Permanent Magnet Technology has completed more than 3000 energy-saving technological transformation cases in industries such as power, metallurgy, petrochemicals, cement, and coal, with energy-saving rates generally reaching 20% -50%. In order to accelerate the popularization of energy-saving and carbon reduction technologies, Wofu Permanent Magnet Technology has also established the "Permanent Magnet Transmission Industry Technology Innovation Center" in conjunction with Suzhou University and CSIC 712 Research Institute. It develops customized solutions for energy consumption pain points in different industries, providing full chain services from technical design, equipment installation, operation and maintenance monitoring for key energy consuming units such as power plants and steel plants, and helping regional industrial green upgrading.

From the development of a single device to the output of energy-saving solutions for all scenarios, from helping individual enterprises reduce costs to promoting the low-carbon transformation of the entire industry, Wofu Permanent Magnet Technology has always taken "technological innovation drives green development" as its mission, injecting permanent magnet power into the realization of the national "dual carbon" goal with practical energy-saving effects.