HOME > Company News > High power permanent magnet speed regulator: operating without faults in the past decade, leading a new era of high efficiency and energy conservation

In the context of pursuing energy conservation, carbon reduction, and efficient operation, the energy conservation and reliability of industrial equipment have become the focus of attention for enterprises. High power permanent magnet speed controllers, especially those based on oil cooling technology, use magnetic non-contact torque transmission to achieve stepless speed regulation within the range of 30% to 97%. They can also be controlled by DCS or PID systems based on input 4-20mA signals to accurately adjust the load speed. This feature enables it to achieve significant speed reduction and energy-saving effects while meeting various process requirements. Through practical application verification at a power plant in Northeast China, it has stood out in the market and achieved nearly ten years of fault free and stable operation, bringing significant energy-saving benefits to many enterprises.

The circulating pump of the second heating network in the first heating station of a power plant in Northeast China was originally in power frequency mode, and the pump has been running at high speed without any speed regulation means. The main problems are as follows: 1. Due to the different flow requirements of the heating network circulation pump at different time periods, the original power frequency mode cannot accurately adjust the speed according to the actual heating demand, and its motor output does not change significantly, which is extremely uneconomical and does not meet the requirements of current energy-saving development; 2. Directly starting the motor causes a significant impact on the system during startup, resulting in poor safety and reliability of the system and high equipment maintenance costs; 3. The system vibrates significantly, causing severe wear on the bearings of the motor and water pump.

To solve the above problems, improve the efficiency and reliability of the heating network circulation pump, and reduce power consumption, it is decided to install a permanent magnet speed controller. After installing a permanent magnet speed regulator, the main advantages are as follows: 1. Permanent magnet speed regulation can achieve stepless speed regulation of the load within the range of 30-97%, meeting the demand for precise speed adjustment in the process; 2. Adjust the load speed according to the input signal to achieve process control and fast response speed; 3. When starting, adjusting the air gap to the maximum can minimize the impact of starting current and greatly reduce the time required for motor starting current; 4. As permanent magnet speed regulation is a non mechanically connected speed regulation device, there is no mechanical hard connection between the pump and motor, and torque is transmitted entirely through the air gap, isolating the transmission of vibration and reducing it; 5. The permanent magnet governor has a simple structure, low failure rate, and extremely low maintenance costs in the later stage; 6. Long service life: The service life of permanent magnet speed regulation can reach 25 years; 7. By accurately adjusting the load speed, efficiency can be improved, pipeline losses can be reduced, motor load can be reduced, and energy-saving effects can be significant; 8. Suitable for various harsh working environments, such as high voltage fluctuations in the power grid, high harmonic content, flammable, explosive, humid, high dust content, high temperature, low temperature, etc. 9. Non contact mechanical connection that does not generate harmonic interference.

Site conditions after installing permanent magnet speed regulator

The circulating pump of the heating network (motor power: 1600kw/1486rpm/183.4A) has a high power and critical cooling. It is equipped with a permanent magnet governor developed and produced by Anhui Wofu Permanent Magnet Technology Co., Ltd. The permanent magnet model WF-TW850 was installed and debugged in October 2016. After being put into operation, it has stable operation, high energy saving rate, and no quality problems.

operating effect

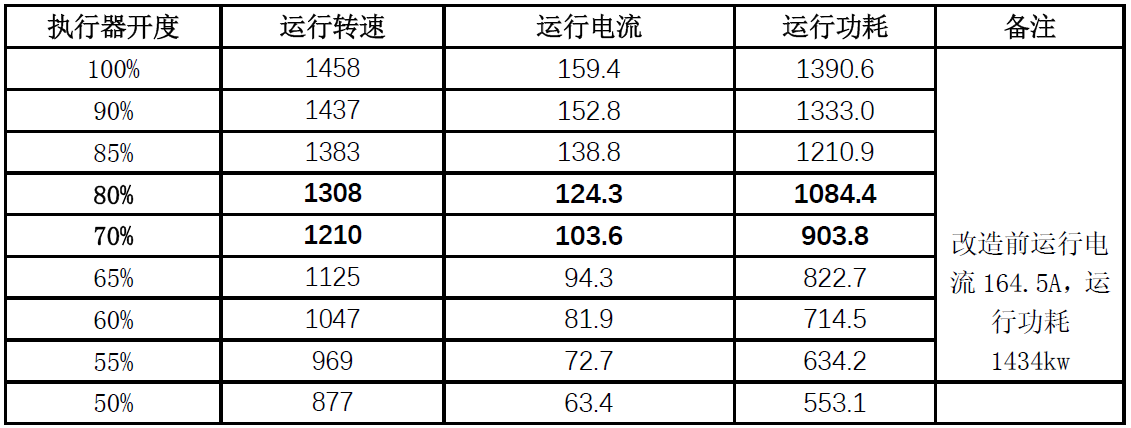

After installing a permanent magnet speed controller, the operating effect is as follows:

After installing the permanent magnet speed controller, the expected goal was fully achieved. From the current operating conditions, the actual power consumption of the motor is 553.1kw~1390.6kw. Normal use is mostly concentrated between 1200-1300rpm to meet the requirements and improve the efficiency of the system. The comprehensive energy-saving rate can reach over 30.7%, and the energy-saving effect is extremely significant. In addition, during the operation of the system, the vibration is reduced (up to 1.3mm/s), and the maintenance workload in the later stage is minimal. Its economy, safety, and reliability have been significantly improved. The project was debugged and accepted in 2016, and has been running without any quality problems since then, which is very worthy of promotion.

It is reported that there are multiple technical routes for domestic permanent magnet governor products, and the disc symmetric oil cooling structure has the highest performance in high-power applications. A representative example is the permanent magnet governor independently developed by Anhui Wofu Permanent Magnet Technology Co., Ltd., which covers energy-saving and technological transformation projects of high-power motors in many fields such as power, metallurgy, chemical industry, cement, coal and carbon, steel, military industry, etc. The successful application cases have reached more than 2000. Whether it is energy-saving rate, product operation stability, or after-sales service reputation, it is a top tier brand. It has been awarded the "Domestic Leading" (certificate number: 202034ZK4474) by the Ministry of Industry and Information Technology, and has won the first batch of advanced applicable technologies in the country, the Ministry of Industry and Information Technology's national industrial energy-saving technology, the national specialized, refined, special and new small giant enterprise, and the national Honors such as intellectual property advantage enterprise.

Permanent magnet speed controllers provide reliable energy-saving solutions for industrial enterprises with their outstanding performance of reliable and stable operation, years of trouble free operation, and significant advantages of high efficiency and energy saving. They lead the trend of green development in the industry and become an important force in promoting energy conservation, emission reduction, and improving operational efficiency in the industrial sector. With the continuous advancement of technology and the continuous expansion of applications, the permanent magnet speed regulator industry will create greater value for more high-energy consumption owners and help achieve the national "dual carbon" goal.